When Seaford was nylon capital of the world

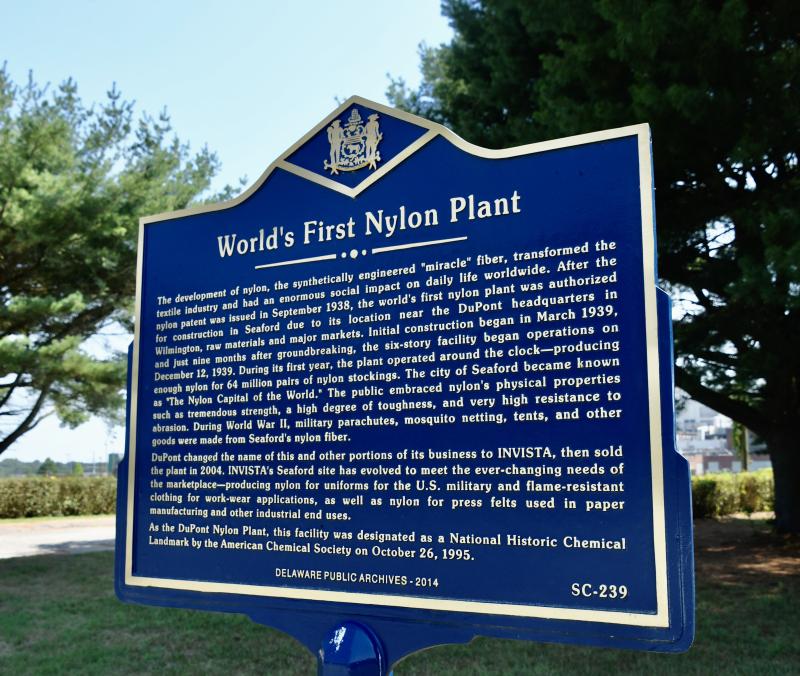

The demand for nylon stockings led to one of the most significant events in the history of Sussex County. On Dec. 12, 1939, the DuPont Company started operations at the first nylon plant in the world in Seaford.

For the next 50 years, the plant provided jobs and good incomes to thousands of people, and not just from Seaford. The plant was the leading employer in the county and also attracted workers from throughout Delmarva.

Seaford had become the nylon capital of the world, and its initial growth can be tied to an insatiable demand for its major product – nylon stockings.

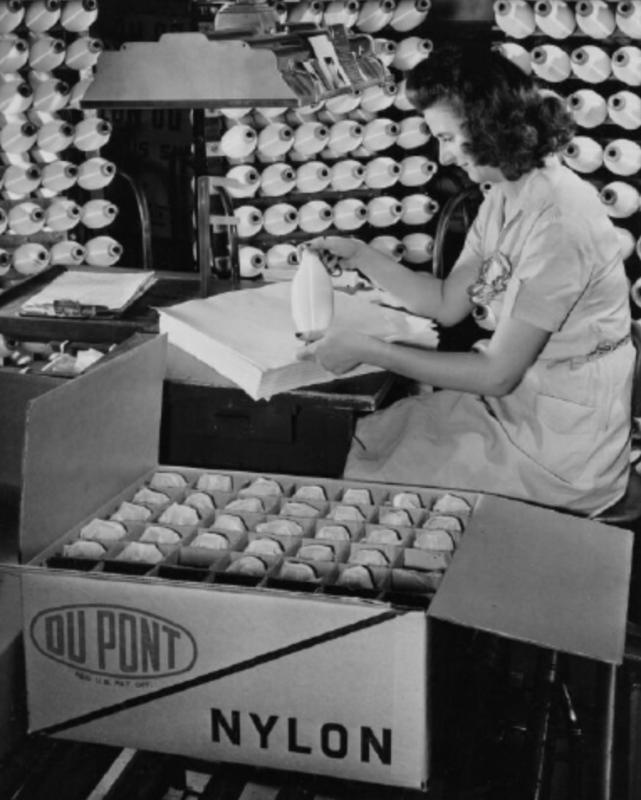

Under the direction of the inventor of nylon, Wallace Carothers, a pilot plant at DuPont’s Experimental Station produced nylon for 4,000 pairs of stockings. They went on sale Oct. 24, 1939, in Wilmington-area stores and sold out in three hours.

Seven months later, the Seaford plant produced enough nylon for 4 million pairs of stockings sold nationwide.

Employment grew from 850 that first year to 4,700 by the 1960s into the 1970s. The plant had its own construction division that employed another 1,200 workers.

Almost overnight, the economy of Sussex County changed.

The plant operated on a 24-hour shift for more than 40 years before early-retirement buyouts and layoffs significantly reduced the workforce.

In the early 2000s, DuPont changed the name of its synthetic fiber division to Invista, and in 2004, it sold the division, including the Seaford plant, to Koch Industries for $4.4 billion.

Open in nine months

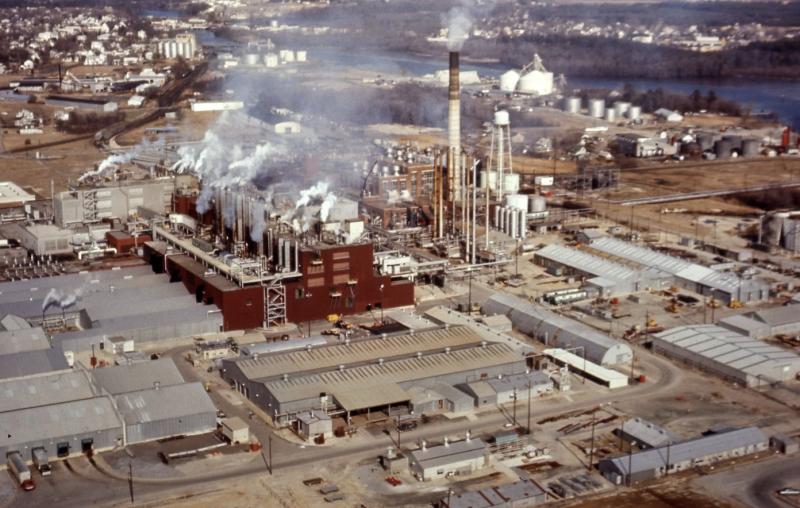

Ground was broken on a 648-acre site just outside city limits for the plant in March 1939, and it began operations in December. It had to be one of the most ambitious construction projects in Delaware’s history, and in record time.

Even before the first yard of nylon came off the spindles in Seaford, DuPont had already announced expansion plans. And it seemed that expansion really never stopped.

You have to consider that DuPont’s investment of $8 million for the plant and many tens of millions of dollars for development of nylon came during the Great Depression. The plant investment was one-sixth of the company’s 1938 net income.

Obviously, there was a lot of competition among towns seeking a way out of the Depression with a new DuPont plant. DuPont officials ultimately selected Seaford because of its proximity to the Nanticoke River, roads leading to major markets, and a railroad, as well as its proximity to Wilmington, the base of all DuPont operations.

Influx of workers

When news got out about the plant being built, hundreds of unemployed workers, desperate for jobs, flooded Seaford even before construction began. They came from far away as Louisiana and Texas to what they called the Cinderella Town, according to the Seaford Historical Society.

It was a struggle to house and feed the influx of people, and even more showed up by spring seeking their American dream. Many Seaford families opened their doors to help house the people.

Seaford went from farming and oystering to a manufacturing town seemingly overnight. The city was expanded to accommodate new housing developments to provide homes for workers.

War time production

After only two years of operation, the Seaford plant was forced to switch to war time production, but there was no slowdown, as workers supplied nylon parachutes, mosquito netting, tents and numerous other military goods.

The revolutionary nylon fibers were used for carpet, lingerie, cords, dental floss, seat belts, fishing line, air bags, auto products and all types of apparel.

The Seaford plant was also the leader in producing Stainmaster, the revolutionary, stain-resistant nylon 6.6 carpet fiber introduced in 1986.

With a $15 million advertising campaign, Stainmaster soon became the standard for carpet worldwide. Lowe’s bought the Stainmaster brand in 2021.

Revolutionary fiber

In simplistic terms, nylon is made from coal, air and water. But the research into developing the fiber was like no other before it. It was five years from the creation of the nylon molecule to the Seaford plant opening, an unbelievably short time.

It was the first totally synthetic fiber for consumer products ever developed, and led the way to creation of thousands of other synthetic fibers over the years.

“Nylon revolutionized the textile industry and led the way for a variety of synthetic fibers that have had a huge impact on the social and economic fiber of everyday life,’’ according to the American Chemical Society.

Big influence on Seaford

DuPont was a unique plant with its own union. Healthcare, retirement and other benefits were unmatched by any other company in the area.

Train cars filled with coal moved along the rails to the plant on a daily basis. The parking lot contained 3,000 parking spaces.

Growing up in Seaford, I could see what influence it had on the city. Thousands of people built businesses and offered services to support the plant.

I did freelance photography for the plant’s newspaper, Threadline, which had its own staff.

The Nylon Capital Shopping Center, located within sight of the plant, was the commercial go-to area in the county.

DuPont opened a country club with nine holes that became the social spot to be and be seen.

Work never stopped with three eight-hour shifts. During shift change, the streets of Seaford were congested with hundreds of workers headed for home.

We knew better than to try to get downtown during shift changes.

If you didn’t work at DuPont, you had a family member or friend who did. Many people were able to live comfortably with the money they made at DuPont. People were able to send their children to college, purchase nice homes and enjoy life.

When the research and development center opened, a wave of PhDs, chemists and scientists came to the city.

Those men became community leaders, serving on the town council and school board.

The end of an era

Worldwide competition caught up with DuPont and in the 1980s, officials began downsizing the Seaford plant, offering early-retirement buyouts at about 100 per year. That led to layoffs, and within 15 years, the employment ranks had been cut to 700 workers. It was sold in 2004 and became Invista.

Recently, Invista officials announced they are looking at options to sell the apparel and advanced textiles unit. The plant no longer makes carpet fiber, but it does provide nylon for U.S. military uniforms, flame-resistant and outdoor clothing, and many industrial uses.

In 2008, Invista cut 400 of its 500 jobs at the plant.

For more information, go to https://www.worldrecordacademy.org/2023/12/worlds-first-nylon-plant-world-record-in-seaford-delaware-423569 and https://www.acs.org/content/dam/acsorg/education/whatischemistry/landmarks/carotherspolymers/first-nylon-plant-historical-resource.pdf.